Re-Engineering des VW APP550

Part 1: Geometry Reconstruction & Efficiency Map

Motivation: Curiosity as a Starting Point

Sometimes, engineering projects don’t start with a specification sheet – but with a simple question.

After Munro & Associates (Link)published their detailed teardown of the Volkswagen APP550 drive unit, I found myself wondering:

How close can you get to the real machine using only publicly available information?

No OEM CAD, No internal data, No test bench measurements.

Just images, videos – and engineering judgment.

From Images to Geometry: Reconstructing the Machine

The FEM model is based entirely on public sources:

teardown videos and high-resolution images

publicly accessible presentations and publications

pictures of physical cutaway models, including exhibits at PCIM Europe 2024

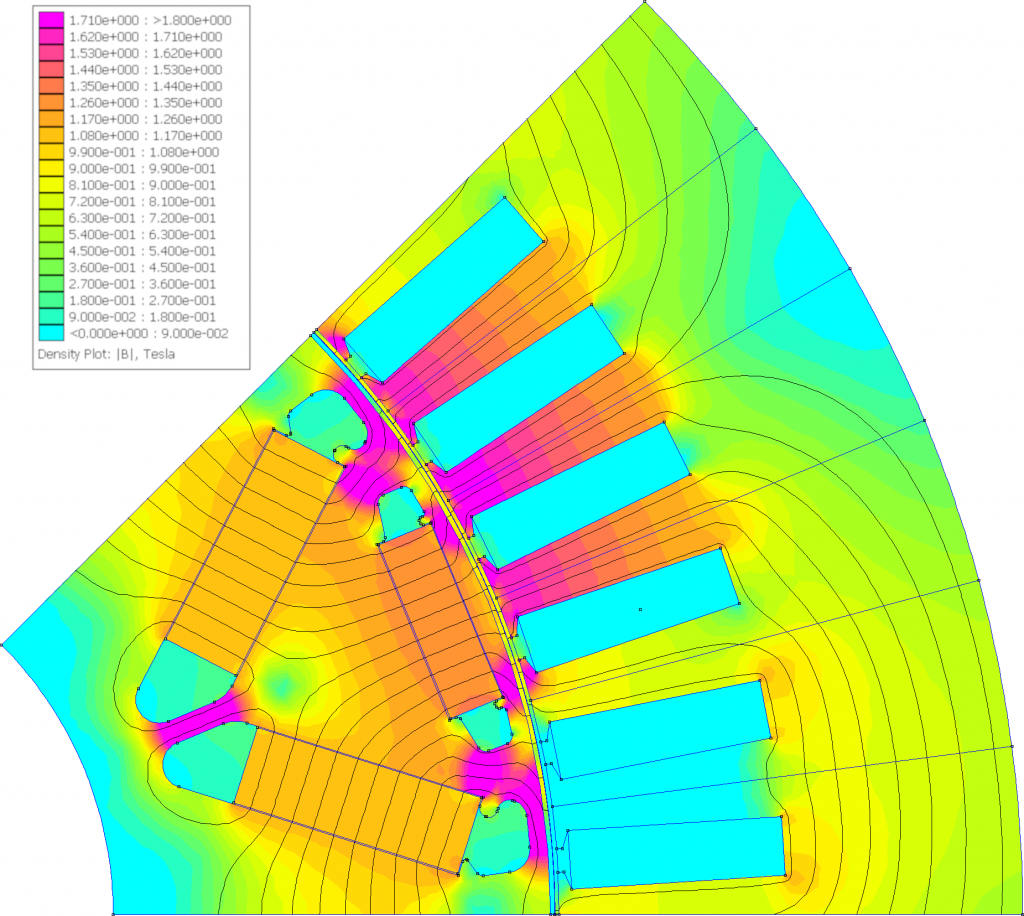

From these sources, the machine geometry was reconstructed step by step and translated into a 2D – FEA model.

Absolute dimensional accuracy is unrealistic – but a physically consistent approximation is achievable.

Key assumptions used in the model:

Electrical steel: NO20

Magnet material: N52-EH

Magnet temperature: 100 °C

DC-link voltage: 380 V

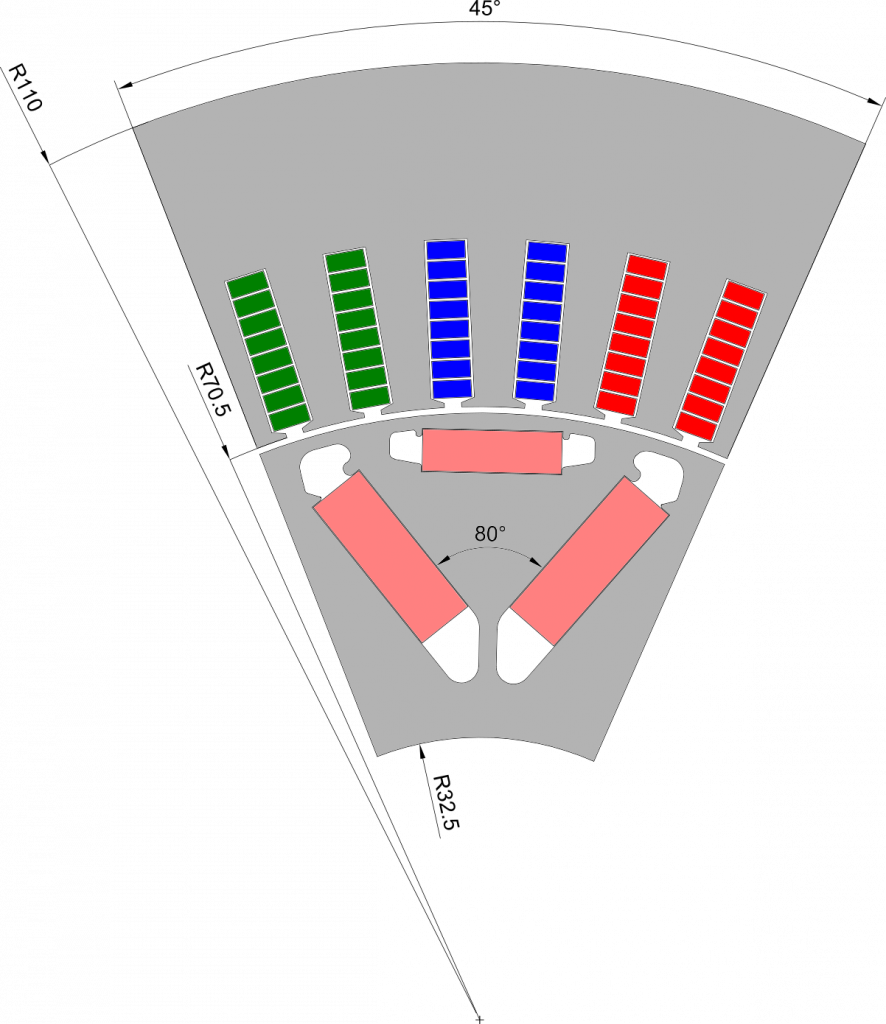

These assumptions strongly influence the results and are therefore stated explicitly. Details of the re-engineered geometry you can take from the provided image.

Results: A Calculated Efficiency Map

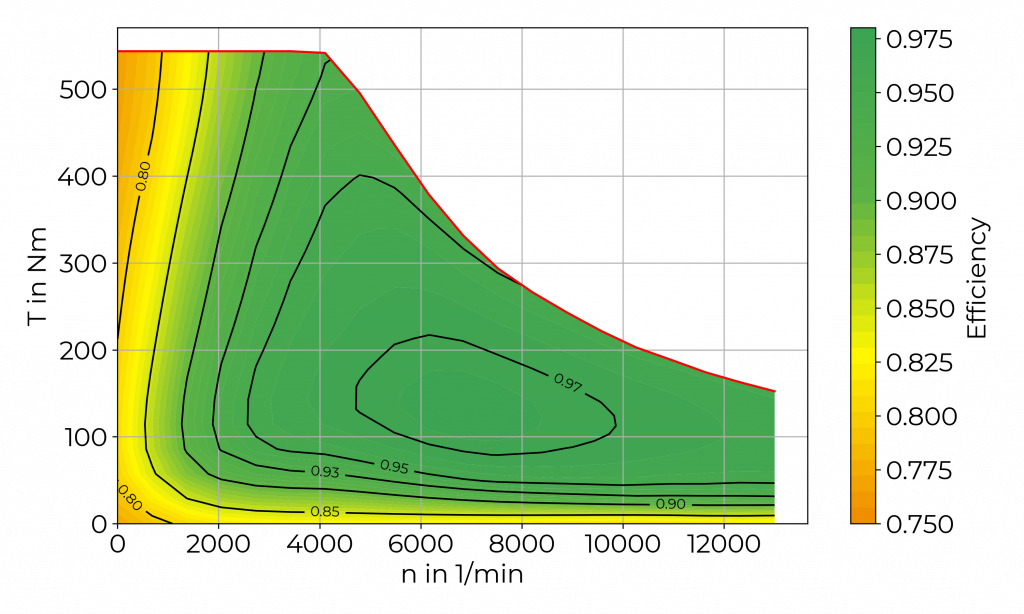

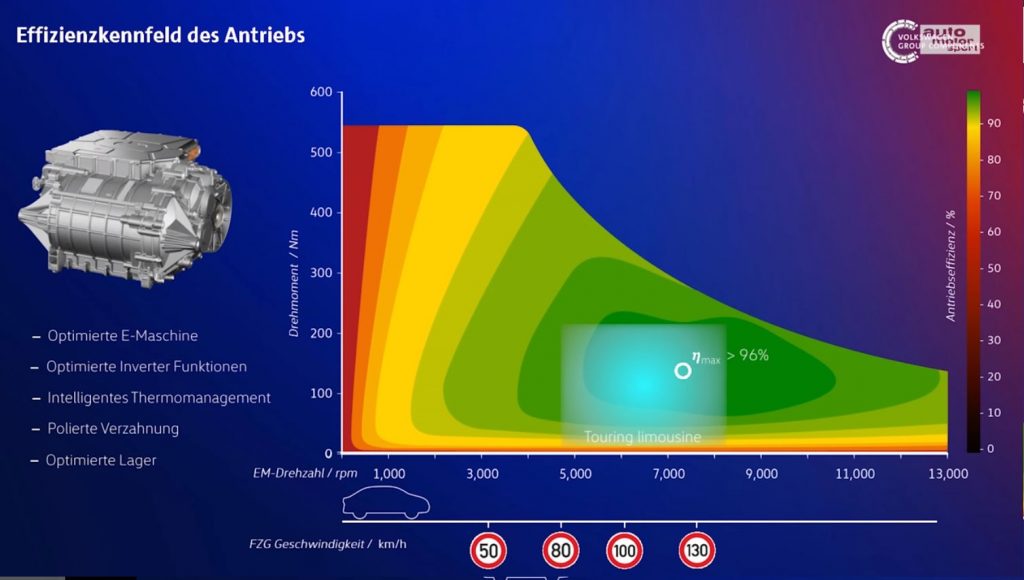

Using the model, an efficiency map of the electric machine was calculated.

The interesting part came during comparison:

maximum torque

base speed and maximum power is reached.

location of peak efficiency

show strong similarities to the efficiency map published by Alexander Bloch (Link) in his analysis of the APP550 drive unit.

Of course, questions remain:

Are boundary conditions truly comparable?

Are material and temperature assumptions correct?

What role do cooling details play?

👉 Still: The fundamental machine behavior is captured surprisingly well.

Further Results:

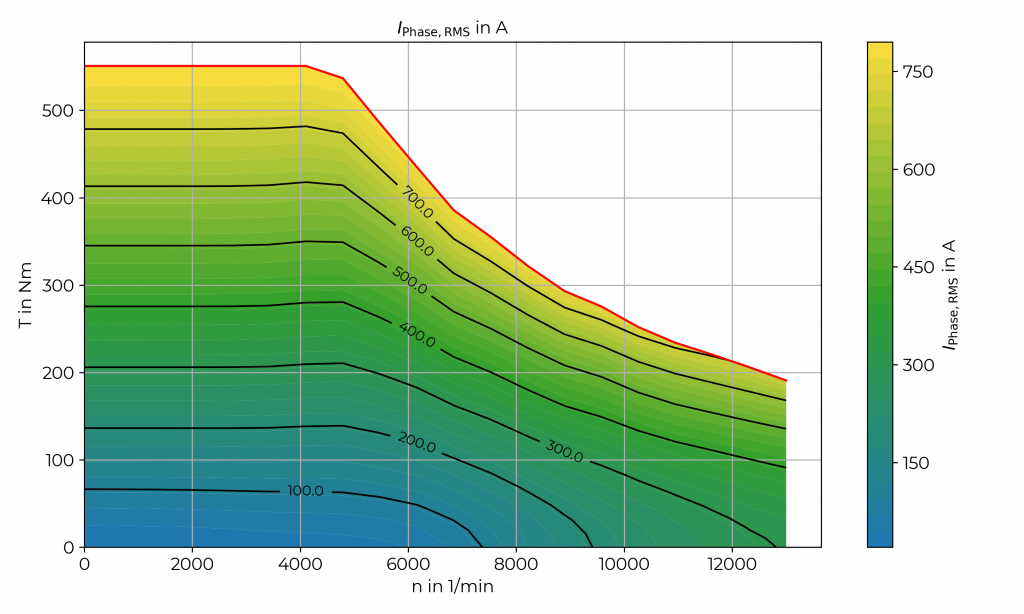

For the 400 V machine a maximum RMS current of 820 A was assumed to reach the maximum torque. This indicates a maximum RMS current density of below 25 A/mm². Considering the effort taken to manage the motor temperatures (jacket and oil spray) it is a realistic current density and matches well the results in the research (Dissertation F. Hoffmann).

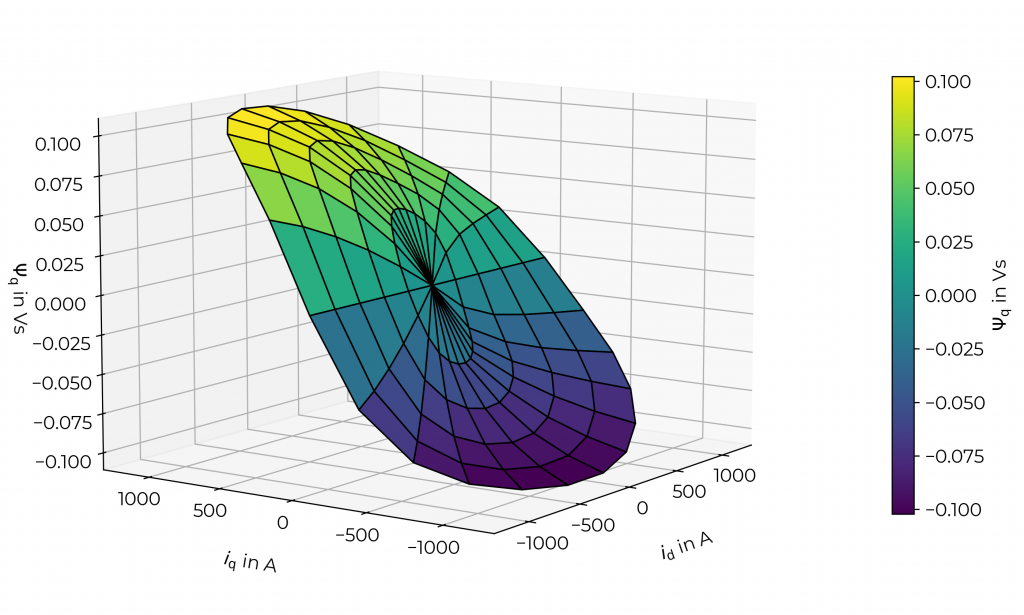

Part 2: Flux and Torque Maps in the dq Reference Frame

After analyzing the geometry and efficiency maps in Part 1, we now take a look into the electromagnetic details of the machine.

This part focuses on the dq maps: why they are essential for machine design and operation—and which characteristic behaviors become visible when analyzing them in detail.

1️⃣ Why dq Maps?

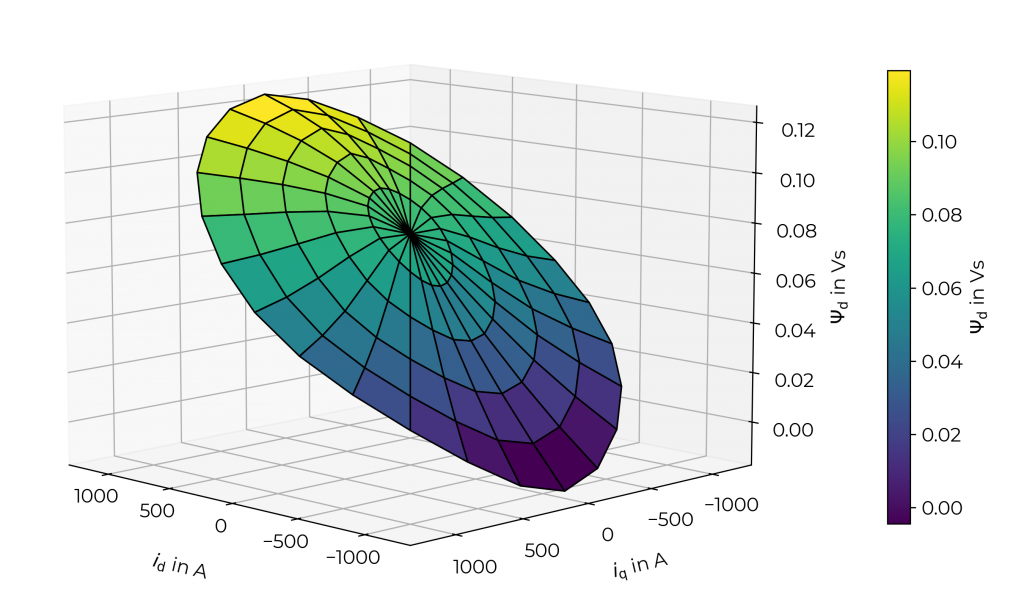

Flux linkage maps in the dq reference frame form the foundation for the design and control of highly utilized, nonlinear electrical machines:

In combination with torque maps, they allow the direct derivation of MTPA (Maximum Torque per Ampere) strategies.

The required voltage at different operating speeds can be efficiently determined.

Optimal operating points can be systematically identified while considering voltage limits.

For nonlinear machines, dq maps are a prerequisite for stable and robust control strategies.

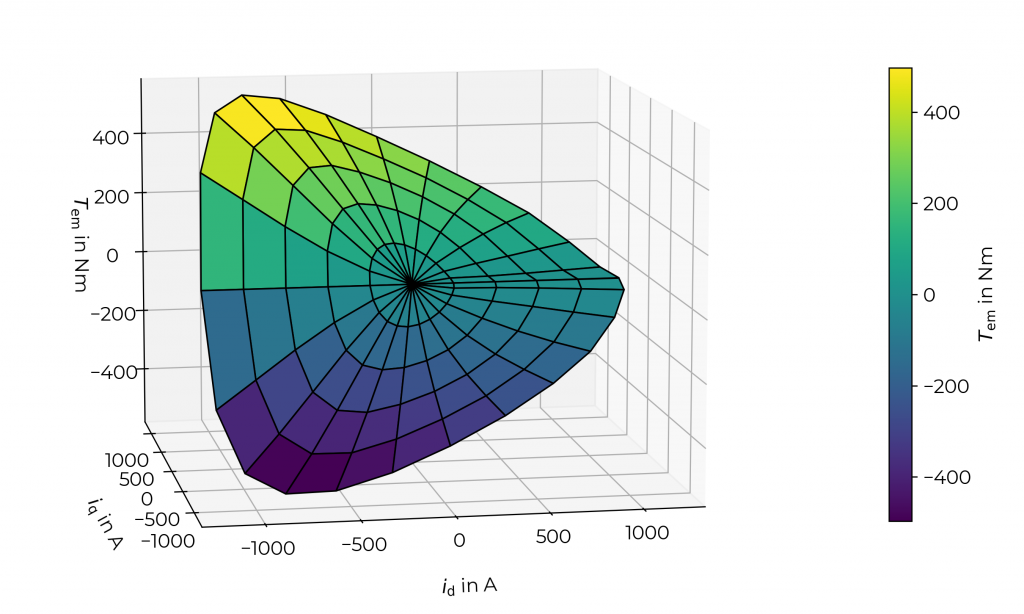

2️⃣ Key Observations from the Maps

The machine exhibits strongly nonlinear behavior and deviates significantly from simple linear dq model assumptions.

Especially in the d-axis flux linkages, it becomes evident that the permanent magnets already heavily saturate the iron. These effects are also clearly visible in the internal flux density distribution of the machine (no-load flux density).

Pronounced cross-coupling effects can be observed: variations in the q-axis current significantly influence the d-axis flux—an unmistakable indicator of high magnetic saturation.

The torque maps reveal a substantial reluctance torque component. Maximum torque is achieved with a significantly negative d-axis current.

Part 3: Currents, Voltages, and Operating Limits

After analyzing geometry, efficiency, and the flux and torque maps, this section focuses on the actual operating points of the machine in the speed–torque domain.

The key question addressed here is:

How do the real current and voltage requirements of the machine evolve with speed and torque—and where do the fundamental operating limits occur?

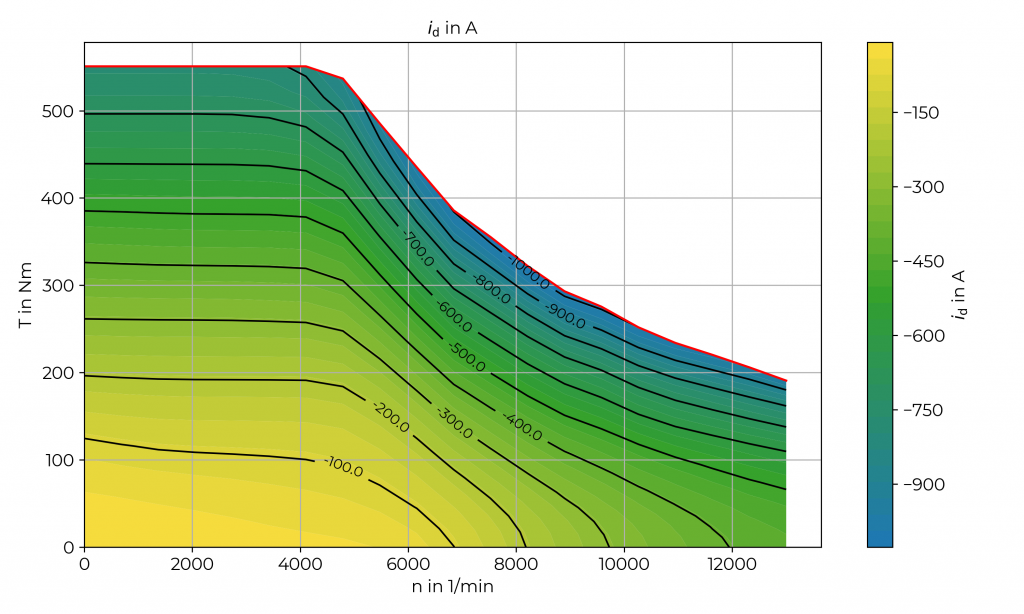

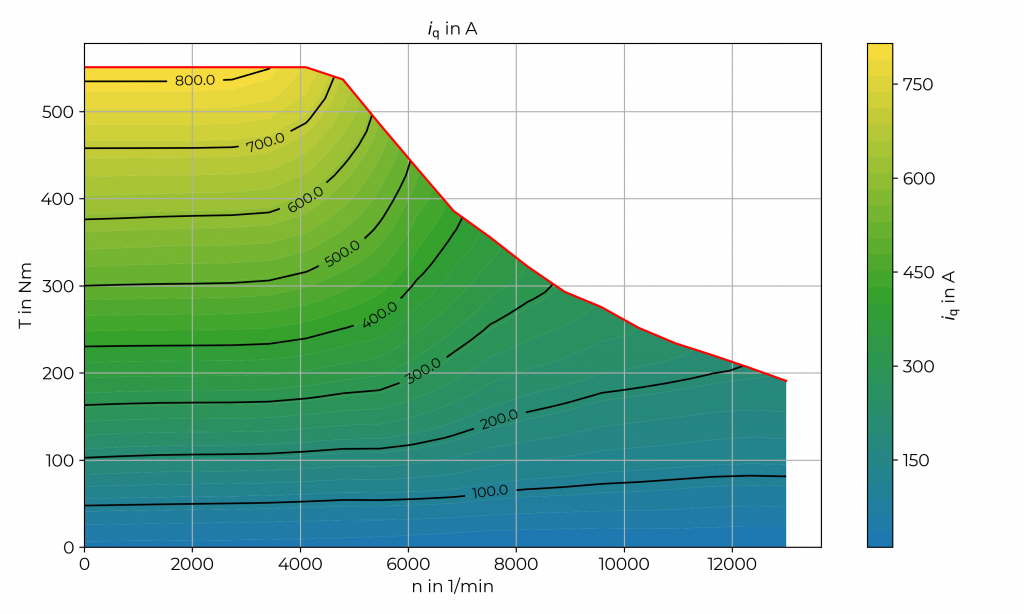

d- and q-Axis Operating Points

The first set of figures shows the resulting d- and q-axis currents as a function of speed and torque, constrained by the admissible operating area of the machine.

Up to base speed, the machine is operated using a Maximum Torque per Ampere (MTPA) strategy with strongly negative d-axis current. This operating behavior is a direct consequence of the pronounced reluctance torque contribution already identified in the flux maps discussed in the previous section.

With increasing speed, the operating point shifts clearly:

The d-axis current is further reduced to limit the induced voltage.

Torque decreases while the mechanical output power remains approximately constant, marking the transition into the field-weakening region.

Phase Current in Operation

The phase current map illustrates the current demand over speed and torque:

A maximum RMS phase current of 820 A enables a peak torque of 545 Nm in the base speed region (n < 4000 rpm).

At higher speeds, torque decreases while the phase current remains nearly constant.

However, the full current capability cannot be utilized up to maximum speed due to voltage limitations of the system.

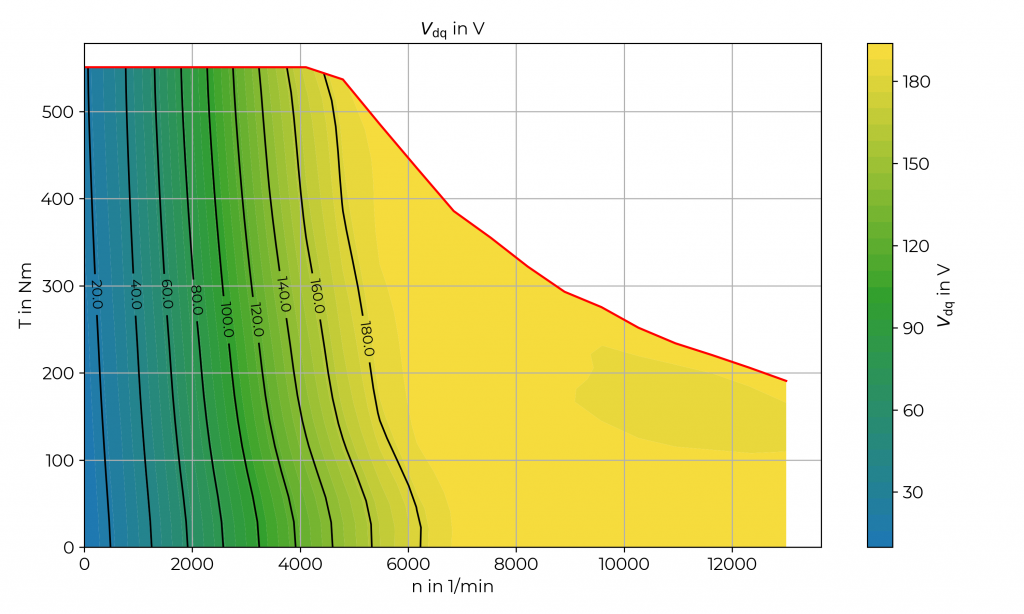

dq Voltage and the Voltage Limit

The voltage map shows the magnitude of the dq-voltage over speed and torque:

Up to base speed, the required voltage increases almost linearly with speed.

Beyond this point, the voltage remains nearly constant, indicating that the system voltage limit has been reached.

In this region, the control strategy transitions from MTPA to MTPV (Maximum Torque per Volt), allowing full utilization of the speed range without exceeding the battery voltage limits.

Implications for Magnet Design

The high negative d-axis currents required in the field-weakening region impose demanding operating conditions on the permanent magnets. In particular, they require high coercivity to ensure demagnetization robustness—an aspect that will be examined in more detail in the next part of this series.

Part 4: Magnet Operating Points, H-Field, and Demagnetization Margin

The previous section clearly highlighted one key aspect of the machine’s operation: Optimal performance requires comparatively high negative d-axis currents.

These currents counteract the magnet flux and shift the operating point of the permanent magnets toward demagnetization. In Part 4, we take a closer look at this effect and assess the resulting demagnetization risk.

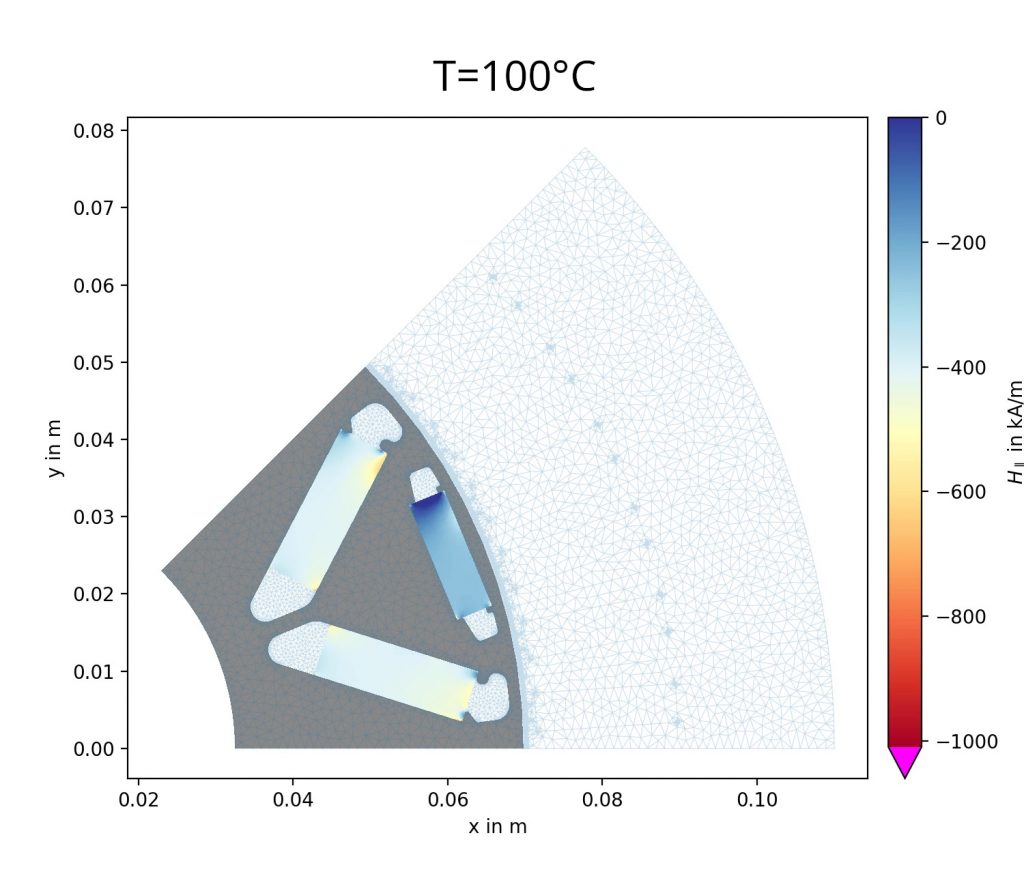

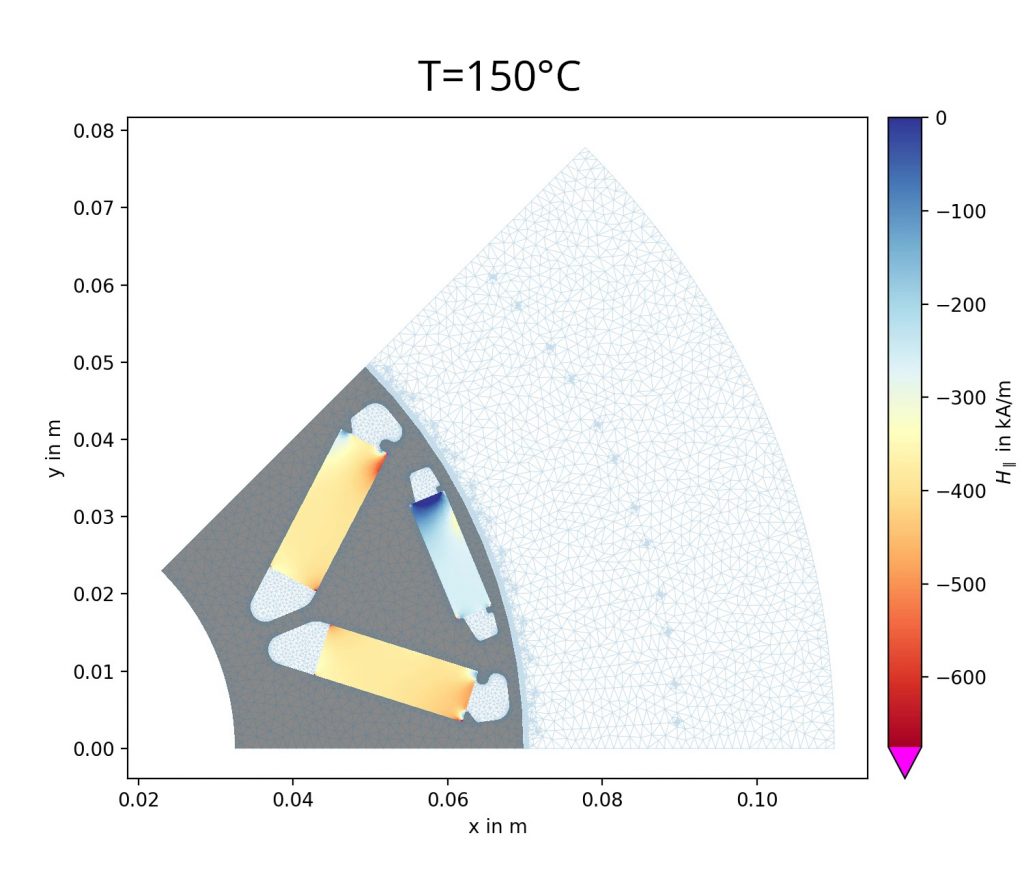

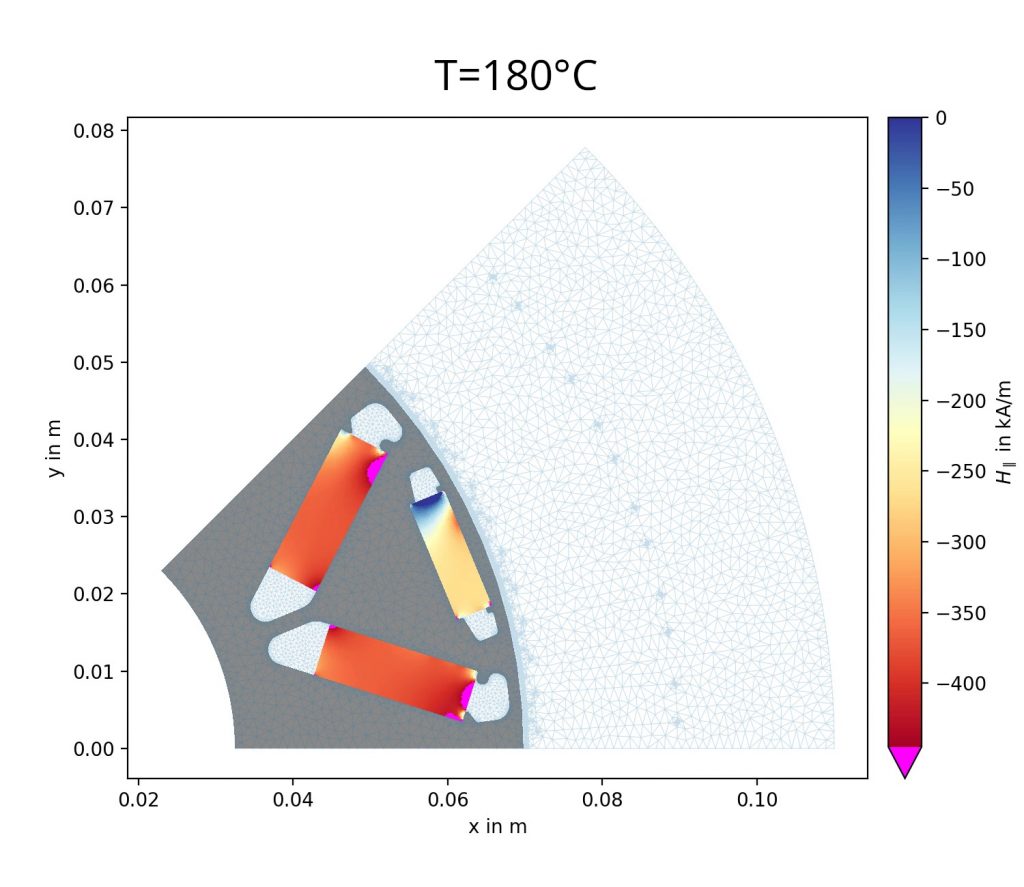

Magnet Operating Points Under Load

The figures show the magnetic field strength H parallel to the magnetization direction within the three rotor magnets of one pole pair.

The evaluation is performed at the machine’s corner operating point:

Speed: 4000 rpm

Torque: 545 Nm

This operating point represents a highly demanding condition combining high torque and strong field-weakening currents.

The three images depict the same operating condition at different magnet temperatures:

100 °C

150 °C

180 °C

Regions highlighted in pink indicate areas where the local magnetic field drops below the knee point of the demagnetization curve during one electrical period.

The evaluation is based on publicly available permanent magnet material data from the Bomatec Group.

Demagnetization Behavior and Local Effects

A key observation is that even at 180 °C, demagnetization remains primarily a local edge effect at the magnet corners.

Only around 3% of the total magnet volume is affected by local demagnetization under these extreme conditions.

This behavior indicates a well-balanced design between performance requirements and magnetic robustness.

Material Selection and Demagnetization Margin

Assuming a magnet temperature class in the EH range, the selected material exhibits high coercivity at elevated temperatures.

Under the assumption of a maximum continuous magnet operating temperature of approximately 150 °C, no permanent demagnetization is expected during normal operation.

The material choice is therefore well suited to the high demands imposed by field-weakening operation and aggressive d-axis current control.

Rotor Temperature in Real Operation

Without considering explicit fault scenarios or exceptional overload cases, the maximum calculated rotor temperature in this setup lies approximately between 150 °C and 180 °C.

Based on experience, the expected temperature during normal operation is closer to 150 °C, as truly critical thermal loads typically arise only during fault conditions such as uncontrolled current events.

This is precisely why demagnetization analysis must be an integral part of electric machine design and validation.

Part 5: Magnet Operating Points, H-Field, and Demagnetization Margin

In Part 4, we saw that high negative d-axis currents during normal operation do not pose a critical risk to the permanent magnets.

But what happens under a real fault condition?

To answer this, I investigated the behavior during an active short circuit (ASC) at constant speed and analyzed both transient and steady-state fault currents as well as the resulting magnet operating points.

1. Active Short Circuit at Constant Speed

The analysis is performed at:

Speed: 4000 1/min

Magnet temperature: 150 °C

This represents a realistic but demanding condition.

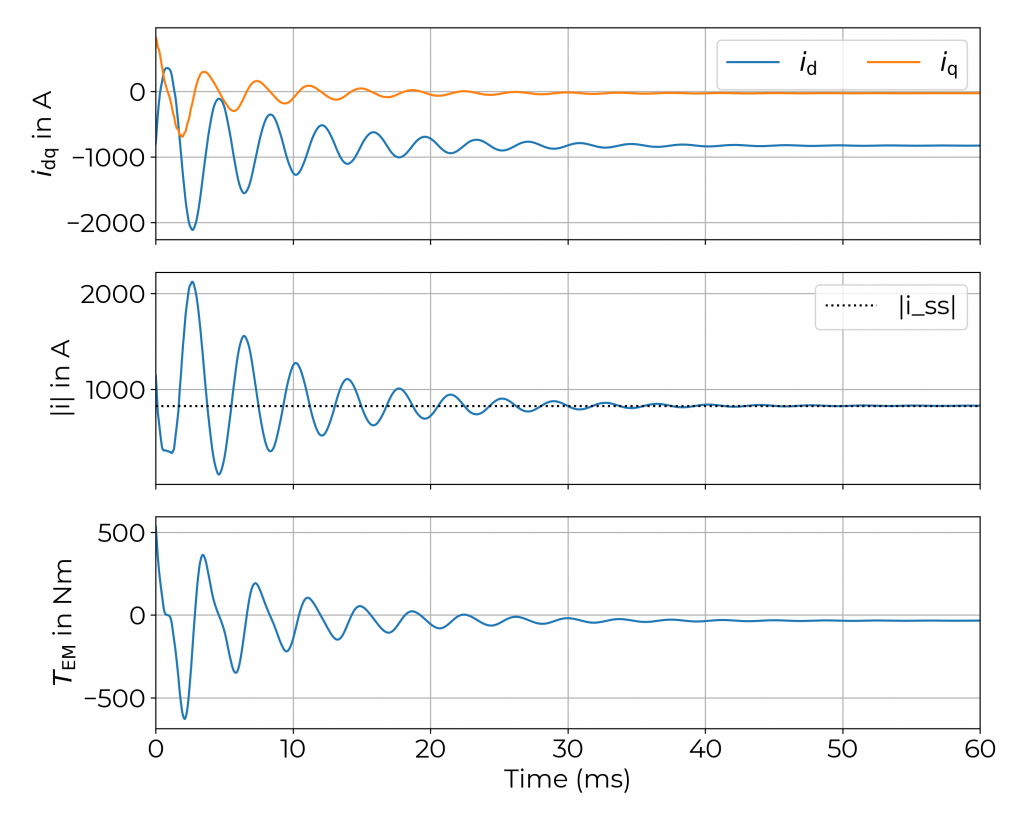

2. Transient Fault Currents

Immediately after triggering the active short circuit, very high current peaks occur.

Peak current: approximately 2100 A

Transition to steady state: after approximately 40 ms

The magnetic risk arises during this initial transient phase.

The extremely high negative d-axis currents (id < –2000 A) shift the magnet operating point deeply toward the demagnetization region. For this reason, the first 20 ms of the event were evaluated in FEM to capture the critical field evolution inside the rotor magnets.

3. Steady-State Fault Current

After the transient oscillations decay, a steady-state short-circuit current establishes itself at 4000 1/min.

This current level lies approximately in the range of rated current and is therefore within the electrical design limits of both machine and inverter.

From a purely thermal perspective, the steady-state active short circuit is not necessarily more critical than rated operation.

The real risk lies in the transient electromagnetic stress.

4. Magnet Operating Point During Fault

The FEM results show how the magnetic field strength inside the rotor magnets evolves during the first milliseconds after fault initiation.

When id drops below –2000 A at 150 °C magnet temperature:

Large regions of the magnet fall below the permissible knee point.

Significant magnet volume is pushed into the irreversible demagnetization region.

Under these boundary conditions, permanent rotor damage cannot be excluded.

5. Implications for System Design

The results allow several interpretations:

The assumed rotor temperature of 150 °C may be conservative; the real operating temperature could be lower.

The active short circuit may not be defined as a survivable fault case.

The primary design objective may be system safety rather than machine preservation.

Personal Assessment

It is entirely plausible that irreversible magnet damage during an active short circuit is considered acceptable, as long as no safety-critical secondary effects occur.

Permanent magnets with significantly higher coercivity at comparable energy density are currently only available with major trade-offs in:

Power density

Cost

Material availability

A substantial increase in fault tolerance would therefore require compromises that may not be economically justifiable.